PRODUCT

BLUESHARK innovative Ceramic Flap Disc is your best choice when grinding stainless steel, titanium, inconel, and other hard metals.The ceramic flap discs using life much longer with " Super-Cooling" grinding ability due to the ceramic grains has a self-sharpening formula.Continuous regeneration of new grain cutting edges over the whole grinding time guarantees consistent surface roughness.

1) APPLICATIONS: Ideal for hard steels including stainless steel. Use for weld blending, light-medium grinding and surface cleaning. High powered angle grinders recommended.

2) ADVANTAGES:

*Extremely high, specific stock removal rate

*Consistent surface roughness

*Very aggressive with less pressure needed

*Fewer disc changes required due to long life

*Super cooling grinding protect work-piece well

3) SPECIFICATION:

![]() T27-FLAT TYPE

T27-FLAT TYPE ![]()

![]()

ORDER NO SIZE GRIT TYPE QTY/BOX

27CA11522 115x22.2 G40~120# T27 Flat 10pcs

27CA12522 125x22.2 G40~120# T27 Flat 10pcs

27CA15022 150x22.2 G40~120# T27 Flat 10pcs

27CA18022 180x22.2 G40~120# T27 Flat 10pcs

![]() T29-CONICAL TYPE

T29-CONICAL TYPE ![]()

![]()

ORDER NO SIZE GRIT TYPE QTY/BOX

29CA11522 115x22.2 G40~120# T29 Conical 10pcs

29CA12522 125x22.2 G40~120# T29 Conical 10pcs

29CA15022 150x22.2 G40~120# T29 Conical 10pcs

29CA18022 180x22.2 G40~120# T29 Conical 10pcs

4) ADDITIONAL INFORMATION:

a) BLUESHARK produce flap discs with different backing plate:

*Fiberglass backing plate - Most popular and it's can reduce vibration and is consumed together with the flaps. High strenghth with light weight.

*Plastic backing plate- With very nice lookings and is trimmable to increasing service life. The ABS plastic backing with very high strength and supply mas safe working performance.

*Nylon - Very familiar with plastic backings but with more light weight.

*Metal HUBS: provides extra high strength and rigid support as needed and normally using for heavy task . Also it can be recycled.

b) 100% Germany original ceramic abrasives materials.

c) Grit size recommendation

40#--Aluminum ,Unalloyed and low-alloy steels,low-strength stainless steel

60#--High-alloy,stainless steel,high-temperature and heat-treated steels

80#--High-temperature alloys

120#--For especially smooth steel finishes(refine polishing)

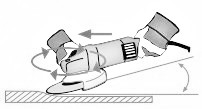

d) Best working angles

(15~30')

(15~30')  (0~15')

(0~15')

For best performance , keep 15~30' when grinding and 0~15' while polishing & finishing.

e) If using flap discs replace fiber discs workings, you should choose one grade coarse grit size. Such like you should using 80# flap discs if

normally using 60# fiber discs.