PRODUCT

BLUESHARK Zirconium Flap Disc is your best choice for universal matching tasks with very high stock removal rates and heavy-duty use. VSM, NORTON, KLINGSPOR, etc sanding papers flap discs available according to customers' professional requirements. The "DOUBLE-BLADE" style flap discs blades specially arranger and let the work-piece's grits easy fly away through the bigger gaps between each " DOUBLE-BLADE" units.

1) APPLICATIONS:

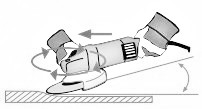

For grinding tasks such as weld seam dressing on planar surface,suitable for duty deburing and beveling work on stainless and high temperature steels, also suitable for deburring and chamfering edges.

2) ADVANTAGES:

*Very high stock removal rate

*Very little surface pressure required.

*Very easy-grinding ability

*Reduce the work-piece surface temperature

3) SPECIFICATION:

![]() T27-FLAT TYPE

T27-FLAT TYPE ![]()

![]()

ORDER NO SIZE GRIT TYPE QTY/BOX

D27Z10016 100x16 G40~120# T27 Flat 10pcs

D27Z11522 115x22.2 G40~120# T27 Flat 10pcs

D27Z12522 125x22.2 G40~120# T27 Flat 10pcs

D27Z15022 150x22.2 G40~120# T27 Flat 10pcs

D27Z18022 180x22.2 G40~120# T27 Flat 10pcs

T29-CONICAL TYPE

T29-CONICAL TYPE ![]()

![]()

ORDER NO SIZE GRIT TYPE QTY/BOX

D29Z10016 100x16 G40~120# T27 Concial 10pcs

D29Z11522 115x22.2 G40~120# T29 Conical 10pcs

D29Z12522 125x22.2 G40~120# T29 Conical 10pcs

D29Z15022 150x22.2 G40~120# T29 Conical 10pcs

D29Z18022 180x22.2 G40~120# T29 Conical 10pcs

4) ADDITIONAL INFORMATION:

a)BLUESHARK produce flap discs with different backing plate:

*Fiberglass backing plate - Most popular and it's can reduce vibration and is consumed together with the flaps. High strenghth with light weight.

*Plastic backing plate- With very nice lookings and is trimmable to increasing service life. The ABS plastic backing with very high strength and supply mas safe working performance.

*Nylon - Very familiar with plastic backings but with more light weight.

*Metal HUBS: provides extra high strength and rigid support as needed and normally using for heavy task . Also it can be recycled.

b) Different flaps-combination achieve various using requirements. Normally combination are

>>>A + A<<< >>>A+Z<<< >>> Z + Z<<< A= Aluminum Z=Zirconia

For best performance , keep 15~30' when grinding and 0~15' while polishing & finishing.

e) If using flap discs replace fiber discs workings, you should choose one grade coarse grit size. Such like you should using 80# flap discs if

normally using 60# fiber discs.